Motor vehicle companies necessitate the highest quality of precision in pieces. A critical aspect is achieving a unblemished surface on bowl-shaped ends, which can be tricky with traditional methods. Our advanced Precision Dished EndAC Polishing Machine addresses this call by offering an mechanized and precise fix. This contraption leverages customized tooling and a managed polishing approach to obtain a polished surface on indented closures, ensuring optimal efficiency and toughness of automotive parts.

- The gadget’s programmable settings empower for precise corrections to the polishing standards, upholding consistency and reproducibility.

- Its tight design enhances workspace performance while easing operator strain.

- Fusion with existing manufacturing techniques is seamless, enhancing production progressions.

Next-Generation Tank Polishing Machines for Stainless Steel Fabrication

In the field of stainless steel construction, obtaining a unblemished and mirror coating is critical. To fulfill this feat, high-efficiency tank polishing machines have appeared as critical machines. These refined machines command cutting-edge technology to effectively eliminate surface blemishes and boost a bright sheen on stainless steel tanks.

- In addition, high-efficiency tank polishing machines are fabricated for optimal output, featuring durable construction, robust motors, and modern polishing heads that reduce surface damage.

- Therefore, fabricators can secure exceptional results with minimal effort, enhancing their production operations and providing high-quality tanks that adhere to the stringent specifications of various areas.

State-of-the-Art Cylindrical Polishing System for Precision Engineering

The request for exceptional surface caliber in precision engineering is constantly mounting. To cope with these rigorous specifications, a new cylindrical polishing system has been invented. This sophisticated device leverages cutting-edge procedures to obtain unparalleled surface flatness. It efficiently eliminates imperfections and enhances the overall performance of cylindrical segments across a wide range of specialties.

- Pros include increased performance, reduced manufacturing outlays, and improved product dependability.

- The system is configured to handle a wide range of materials, including metals, ceramics, and plastics.

- Handlers can easily fine-tune the polishing standards to obtain the desired surface.

This advanced cylindrical polishing system represents a significant development in precision engineering, helping manufacturers to produce units of exceptional standard and functionality.

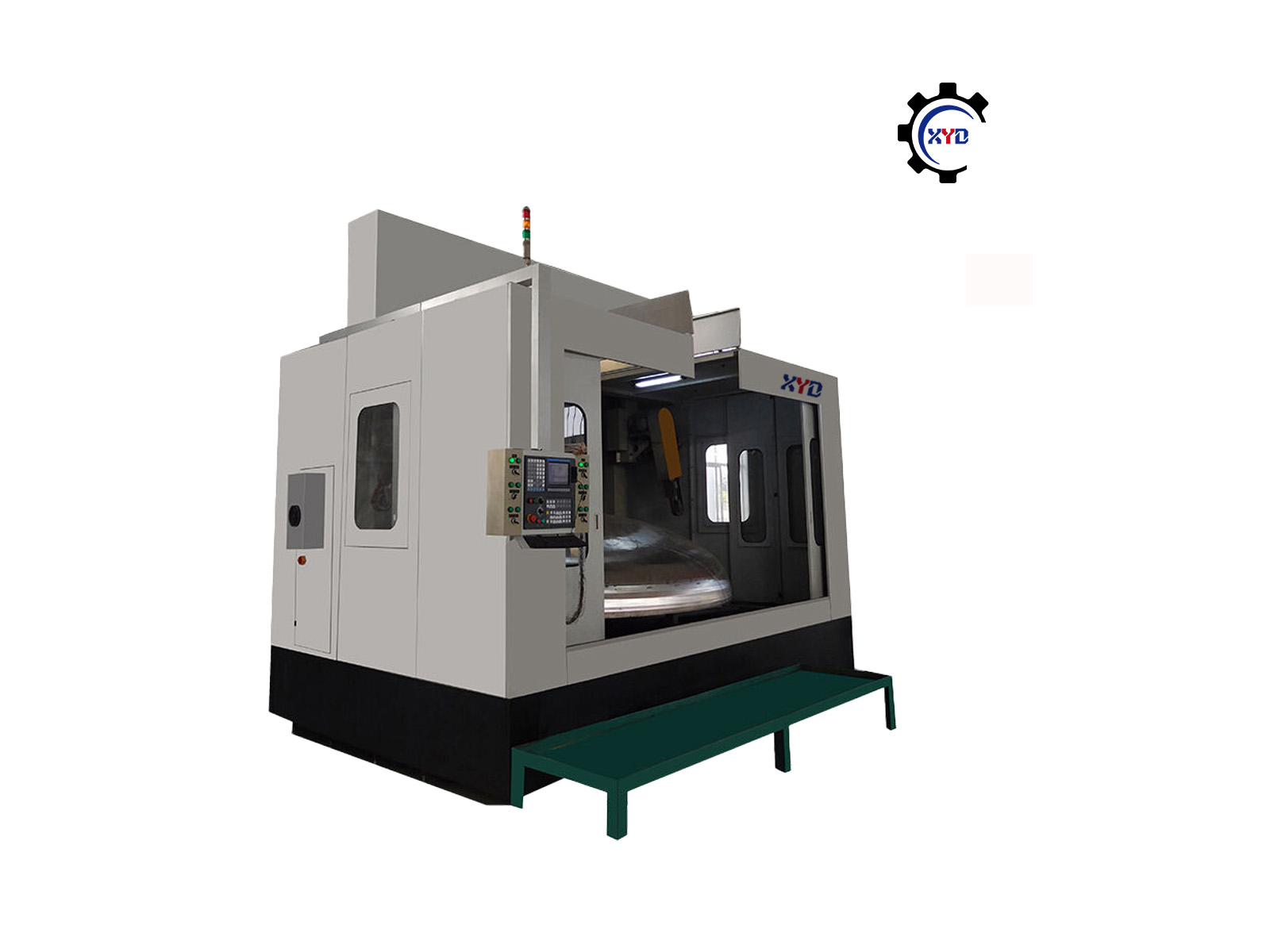

Robotic CNC Polishing Solutions for Complex Shapes

Gaining a seamless polish on intricate structures can be a demanding task. Traditional polishing processes often struggle to deliver consistent results on complex patterns, bringing about time-consuming cycles. However, the advent of high-tech CNC polishing solutions has improved the industry, empowering manufacturers to achieve unprecedented measures of accuracy and efficiency.

These high-tech systems employ CNC machining technology to carefully refine surfaces with minimal operator intervention. Equipped with automated spindles and a variety of polishing tools, CNC machines can seamlessly handle even the most demanding configurations.

What's more, these solutions offer upgraded control over parameters such as pressure, speed, and tool path, securing consistent results across different materials and complexities.

- Outcomes of automated CNC polishing include:

- Heightened precision and surface caliber

- Reduced cycle times and production costs

- Enhanced product consistency and repeatability

- Higher design flexibility for complex shapes

Durable Tank Polishing Machine for Industrial Applications

For demanding industrial contexts where operation is indispensable, a heavy-duty tank polishing machine is an required tool. These machines are specifically designed to handle the loads of frequent operation in extreme environments. Equipped with durable construction and high-torque motors, they can effectively eliminate rust, paint, and additional contaminants from tank surfaces, guaranteeing a smooth and sanitary finish. A variety of devices are available to accommodate different tank sizes and contours, making them versatile for a wide range of applications.

Next-Gen Adaptive Dished End Polisher

Our cutting-edge Dished End Polisher employs sophisticated Adaptive Control Technology to deliver unparalleled efficiency. This tool continuously adjusts the polishing process in real time, securing optimal surface finish for a wide range of products. The Adaptive Control Technology facilitates the adjustment of key settings, such as pressure, speed, and oscillation, to achieve reliable results every time.

- Assets include:

- Improved surface finish quality

- Lessened polishing time

- Augmented control over the polishing process

- Adaptability for a range of materials and applications

Precision CNC Polishing Equipment for Enhanced Finishes

A CNC polishing instrument is a state-of-the-art tool used in various markets for producing high-quality surface finishes. These machines utilize computer numerical control (CNC) technology to meticulously polish surfaces, wiping out imperfections and establishing a smooth, refined appearance. The heavy-duty design of CNC polishing machines enables for flexible production.

- Industrial applications

- Plastics

- Refining details

The automatic nature of CNC polishing machines delivers consistent results, reducing human error and increasing efficiency. By using a variety of accessories, these machines can address a comprehensive set of surface styles and resources.

Large-Diameter Cylindrical Polishing Machines

Manufacturing and polishing large diameter cylindrical components often needs specialized equipment. These machines are engineered to meet precise accuracy levels on objects with significant girth, employing a variety of rotating tools.

The choice of cylindrical polishing equipment varies with the specific material and desired outcome. Some common types include cylindrical grinders, each offering distinct advantages for deburring edges.

- Mounting devices are essential to securely hold large diameter pieces throughout the processing process.

- Controlling spindle velocity and feed are critical for delivering consistent results.

Fast-Track Dished End Polishing Machine for Mass Production

In contemporary swiftly changing manufacturing industry, the push for high-performance high-volume production operations is essential. To satisfy this expectation, manufacturers are leveraging cutting-edge technologies like high-speed dished end polishing machines. These modern tools deliver exceptional accuracy in a time-sensitive manner, promoting consistent quality and first-class surface finishes for a vast range of components.

Manufactured to handle large production runs with remarkable speed, these machines make use of advanced polishing techniques to generate one-of-a-kind finish required for demanding applications. Essential features include high-speed spindles, intelligent control systems, and innovative sheening pads that work in synergy to maximize effectiveness.

Additionally, these machines often incorporate automation capabilities for increased yield and reduced labor costs. This combination of speed, accuracy, and digitization makes high-speed dished end polishing machines a vital asset for manufacturers looking to improve their production processes and follow the growing calls of the market.

Acute CNC Polishing for Aeronautics and Clinical Devices

In the stringent fields of aerospace and medical device construction, surface standard is paramount. CNC polishing furnishes a highly exact and solid method to realize the exacting polishes required for these critical applications. By harnessing advanced CNC machining technology, manufacturers can create surfaces with exceptional evenness, calibration, and longevity. This process supports the production of components that fulfill stringent demands for efficiency, reliability, and integrity.

- demands conditions demands preferences specifications

- As well, CNC polishing boosts the decay resistance and biocompatibility of substances used in aerospace and medical devices.

- Accordingly, it plays a vital role in extending the lifespan and enhancing the functionality of these products.

Adaptable Cylindrical Polishing System for Customization

Highlighting a revolutionary strategy to cylindrical polishing: the Modular Cylindrical Polishing System. This leading system allows unparalleled customization, modifying to your specific preferences. With its interchangeable design, you can conveniently adjust the polishing heads, items, and parameters to obtain the intended finish for your cylindrical objects.

- requirements specifications tank polishing machine criteria

- Asset1

- Pro2

- Gain3