Embarking this examination about rigorous surface treatment approaches for processing industries

Securing stable consequences regarding one's manufacturing procedures? Exactness enhancement systems are critical for completing first-rate component excellence along with increased effectiveness. The firm furnish a extensive collection consisting of modern systems, like chemical passivation, material smoothing, including precision cutting, capable of tackle even the most required requirements. The dedicated specialist team journies with buyers to construct made-to-order polishing outlines planned to increase surface traits and maintain accurate integrity. At last, these thorough solutions contribute to lower charges and boosted functionality for your firm.

Fundamental Seam Sterilization Methods & Instruments

Right solder cleaning is undeniably indispensable for preserving the integrity of any fabricated bond. These way removes remnants, porosity, and other adulterants that can impair durability. Multiple procedures exist, including operated scrubbing with weld tools, and electric grinding. Focused gadgets, such as transportable hydraulic discs, fine scrapers, and scale blasters, are frequently employed for more robust results, particularly on massive welds. What's more, liquid solutions can be executed to further extract stubborn build-up. Opting for the optimal technique and accompanying equipment depends on the manufacturing component, depth, and necessary surface.

Comparable Concepts:

- Construction Analysis

- Joining Practice

- Bonding Safety

Manufacturing Smoothing: Processes & Equipment

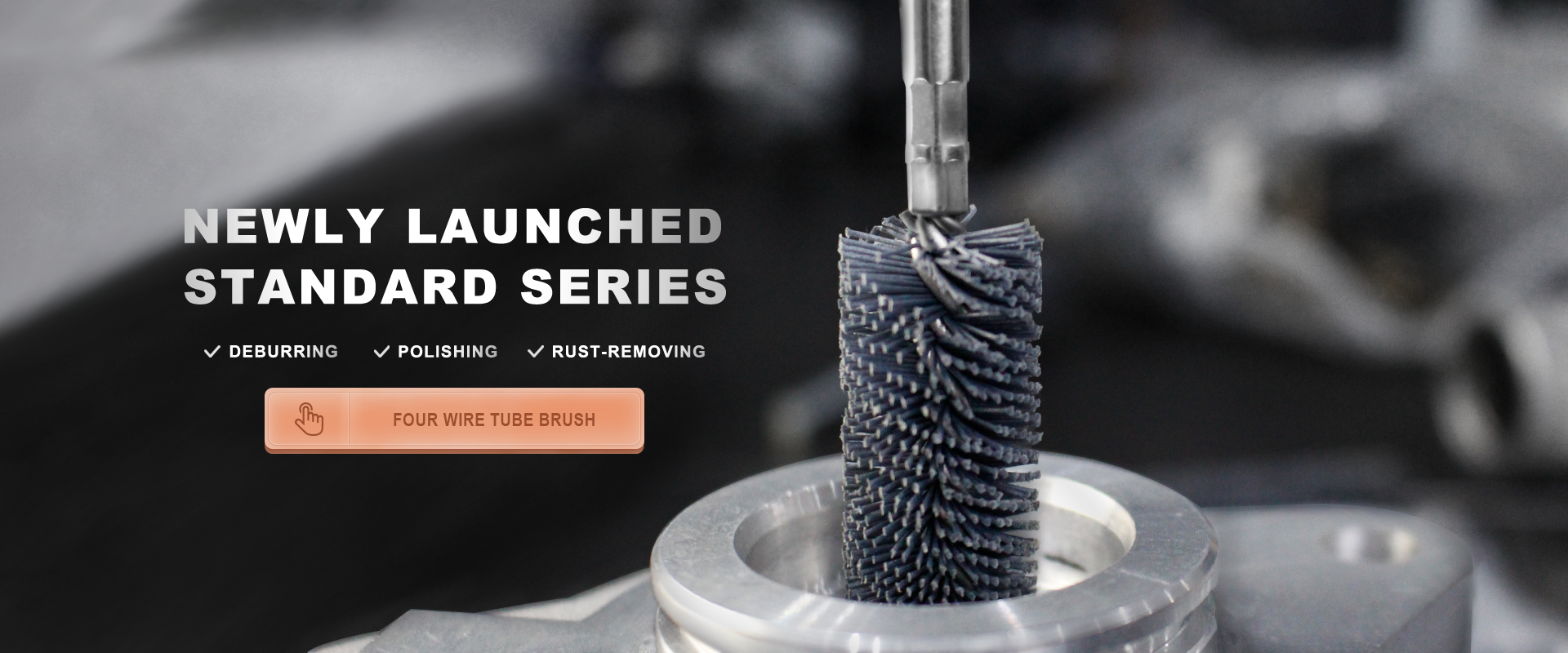

Achieving a smooth, functional top layer on shaped parts is crucial, and deburring plays a vital purpose in that process. Formerly, this was a manual, labor-intensive task, but modern metal fabrication operations increasingly leverage advanced edge-breaking technologies. These procedures range from simple manual brushing and grinding to sophisticated automated systems employing automated deburring assemblies and even abrasive spraying techniques. Ultrasonic non-contact cleaning offers a precise solution for delicate modules, while burner deburring is frequently used for strengthened compounds. The selection of the appropriate edge smoothing system depends significantly on the composition, part outline, and desired condition. Moreover, understanding the genesis of burr formation—often related to pattern design or assembly parameters—can help avoid them altogether.

Electrolyse Strip Brush Applications

Electric cleansing strip mechanisms find multiple utility across a scope of industries, largely due to their gentle yet effective action. Specifically, they excel in removing stubborn burrs from stamped metal units, preparing interfaces for subsequent application processes like powder covering. Beyond deburring, these brushes are frequently used for fine surface conditioning prior to welding, offering a superior alternative to abrasive systems that can introduce surface irregularities. Furthermore, their ability to exhaustively remove scale and oxides makes them valuable in tending operations on enormous equipment.

Exterior Refinement for Crucial Components

Securing utmost performance and extended longevity for paramount machine fragments frequently necessitates focused surface refinement techniques. This isn't merely about aesthetics; it’s about altering the subtle structure of the element to reduce coefficient enhance decay resistance, and improve all-encompassing functionality. Several approaches, including refining, encasing, and photon texturing, can be precisely applied depending on the particular application and the targeted outcome. The selection of a definitive refinement method must always consider the material's properties and the running environment to stop unintended consequences and boost the component's trustworthiness.

Robotic Joint Cleaning Processes

The demand for consistently high-quality welds in modern production environments has spurred significant advancements in seam post-processing techniques. Mechanized preparation processes are rapidly gaining popularity as a proposal to traditional, labor-intensive methods like abrasive blasting or manual grinding. These advanced systems often incorporate technologies such as laser treatment, high-pressure waterjet scouring, or specialized abrasive application, ensuring efficient and precise residue cleansing without damaging the underlying fusion. Implementing these robotic solutions leads to reduced labor costs, improved defense, and a more consistent quality that directly impacts the mechanical capability of the final good. The ability to integrate these tools into existing production lines further enhances their appeal across a wide range of industries, including electronics and heavy machinery.

Deburring Components for Maximum Effectiveness

In an effort to ensure ideal results from your materials, deflashing is a critical procedure. Flanges, a frequent byproduct of the shaping process, can affect operation, result in operational concerns, and poorly disturb exterior look. Therefore, complete smoothing – which may involve specialized systems or automated tools – is urgent for giving a premium finished component fit for its specified duty. This measure not only enhances work but also curtails the likely for failure.

Accurate Decontamination with Ribbon Scraping Procedures

Completing remarkable purity in critical processing fields often requires professional strategies. Wipe brush solutions offer a strong method to eradicate dust from intricate sections. These leading applications utilize purpose-built cleaners to provide unchanging interaction – crucial for accurate sanitation and guaranteeing material level. Consider the benefits of blade brushing procedures for your next clarification requirement.

Cathodic Cleaning for Welds & Surfaces

Cathodic deburring offers a forceful method for cleaning welds and various substance categories. This process, fundamentally harnessing electrochemistry, eradicates oxides, scale, remaining welding fumes, and other foreign bodies that can obstruct following processes like painting, review, or further fabrication. Unlike abrasive processes, electrolytic scrubbing provides a careful action, minimizing harm to the base stock and leaving a remarkably immaculate surface. It's especially worthy for complex forms and difficult areas where manual scraping would be difficult. A carefully adjusted electrolyte liquid and electrical current are critical for achieving uniform results.

State-of-the-art Molding Deburring Methods

Apart from traditional hand deburring, modern casting facilities are increasingly employing sophisticated processes to achieve top-notch edge finishing. These sophisticated deburring methods often involve a combination of automated devices and precisely controlled conditions. Energetic deburring, for instance, offers exceptional accuracy and allows for elaborate geometries to be flawlessly cleaned, minimizing material removal and maximizing unit integrity. Furthermore, mechanized deburring cells, utilizing oscillating tools, are becoming prevalent, providing increased throughput and uniform results, particularly for large-scale production runs. The selection of the appropriate polishing method depends heavily on the manufacturing ingredient, product geometry, and desired look characteristics.

Improved Precision Coating and Stripe Bristle System

The ongoing pursuit of surface finish in modern manufacturing demands ever more expert strategies. Among these, precision enhancement utilizing linear scrubbing process stands out as a effective solution. This approach, frequently employed across diverse industries like defense, offers distinct advantages in achieving steady material wear, shining, and smoothing results. Unlike traditional modes, strip conditioning technology allows for highly controlled material wear and the ability to access elaborate geometries with a extent of accuracy previously unattainable. Furthermore, advancements in fiber electing and powertrain plan continue to expand the applications of this critical surface treatment strategy.

honing brush

honing brush